End of Line

End of line safety and performance begin with Burke Porter

Burke Porter has been supplying custom equipment, service, and support for automotive end of line testing since 1953. No one is more capable to tackle your toughest challenges and unlock performance.

Speak with an ExpertTrusted by leading brands

From best-of-breed to best-in-class

Ascential Technologies has combined Burke Porter Group's sector-leading brands, pooling their collective knowledge and experience to support our commitment to envisioning, designing, and building the most innovative automotive solutions for our customers'

greatest manufacturing and design challenges.

Why Burke Porter End of Line Testing?

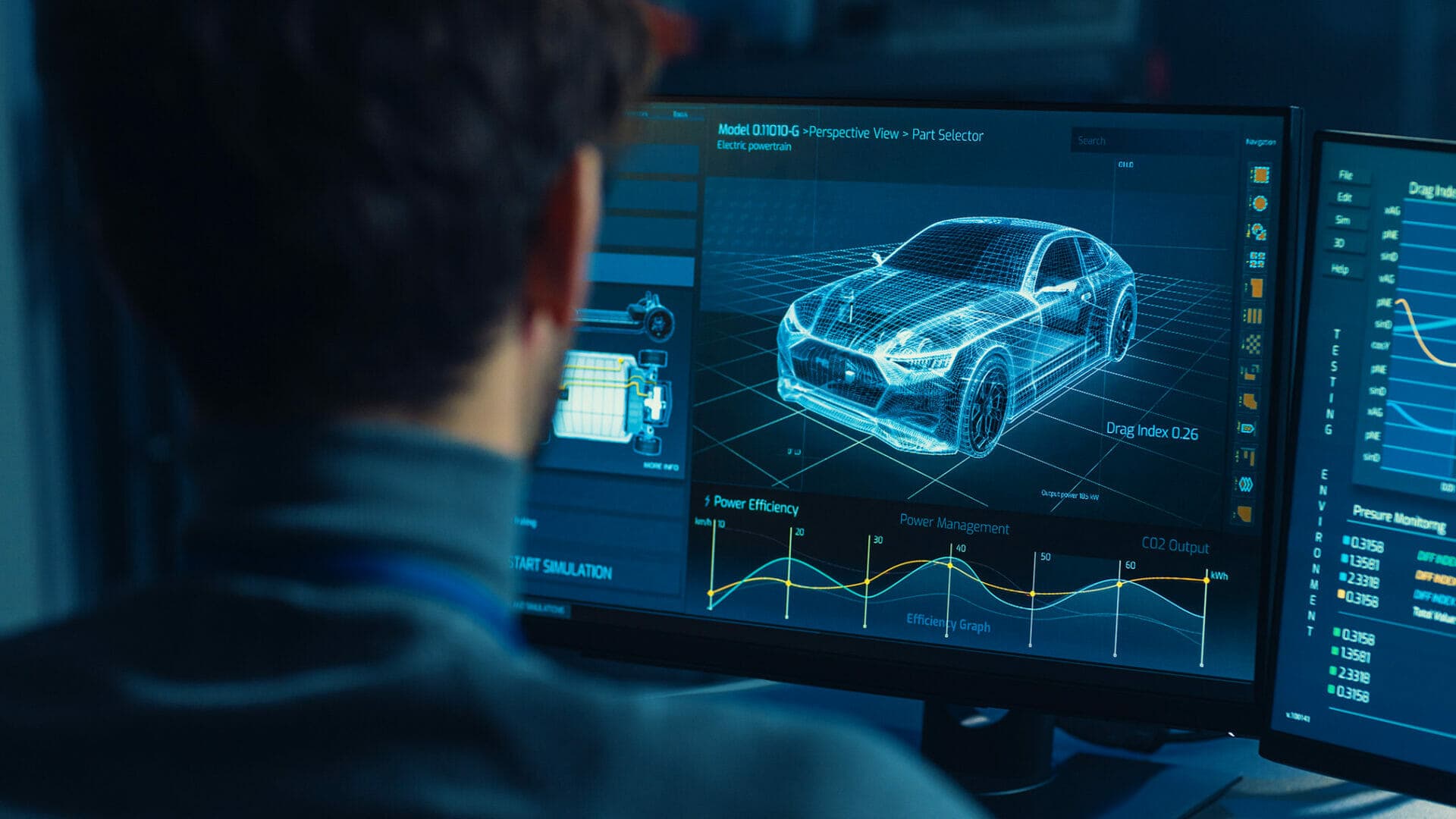

With the rise of electric and autonomous vehicles, and amid increasingly intense regulatory scrutiny, automotive companies know that safety and performance are more critical than ever. That’s why established titans of transportation and disruptive innovators alike count on Burke Porter for our end of line testing solutions. We continue to set the standard of innovation in automotive testing. Our solutions simulate real-world road conditions and provide precise, repeatable test results in a production environment – often performing hundreds of tests in a matter of minutes that represent the final validation before a vehicle leaves the facility.

Built to outperform

Burke Porter end-of-line solutions embody unmatched durability, forged through seven decades of field-tested excellence and with the ability to deliver decades of top-notch performance. We ensure that your operations run seamlessly and efficiently, no matter the challenge. When failure isn’t an option, you can count on Burke Porter.

Flexible to your needs

No customer is the same. No site is the same. That’s why we empower each location and plant engineer to customize solutions to your demanding specifications. With our uniquely decentralized approach, we bring the same uniform rigor with specialization to operate in local languages and with specific manufacturer expertise – delivering agility, global reach and solutions suited to your requirements.

Unmatched scale and consistency

We are where you are, whenever and wherever you need us. Our decentralized approach also enables use to replicate machines and processes in any or all of your plants across North America, Europe and Asia, reducing the time and cost required. Our strategic advantage triples our capacity compared to competitors, ensuring efficient and responsive support for clients across the globe.

End of Line Products

End of Line

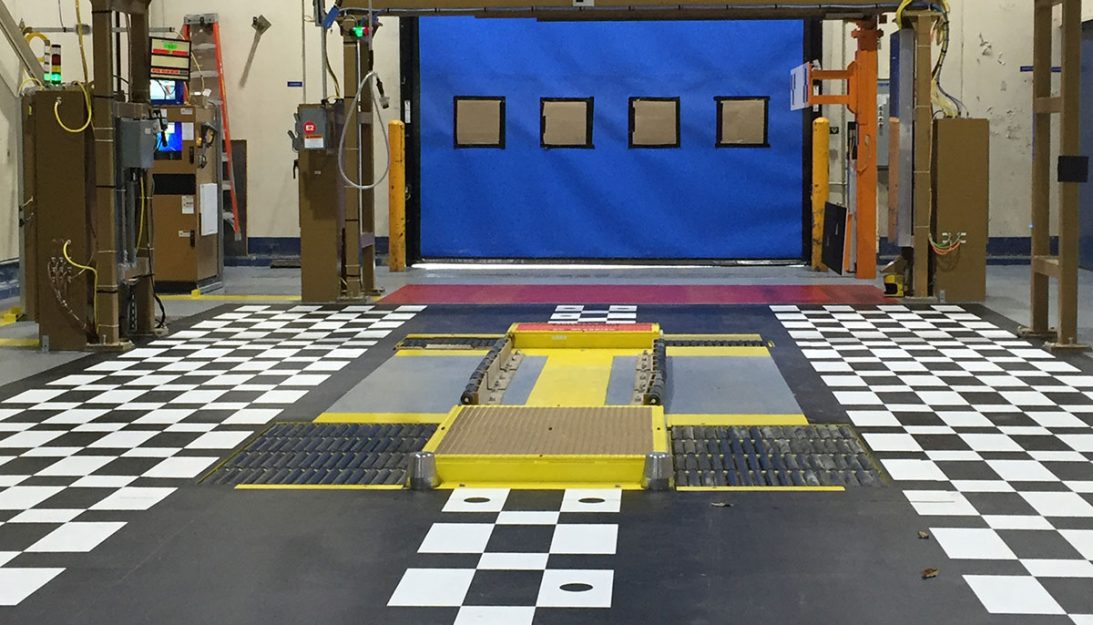

Advanced Driver Assistance Systems (ADAS)

Our systems support a large range of driver assistance systems and offer unparalleled accuracy when calibrating or teaching all integrated sensors. Our smart technology can be used standalone or integrated into NCA systems.

Learn moreEnd of Line

Test

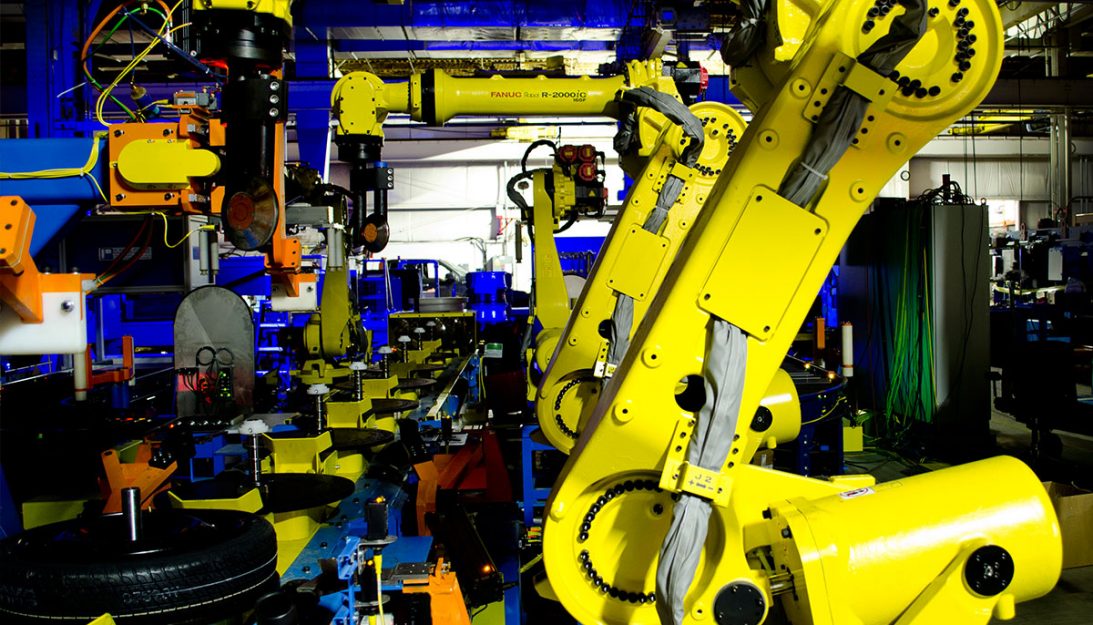

Auto Toe Set Systems

Our robotic Auto Toe Set system (ATS) consists of two robots with torque gun end-effectors used in conjunction with BEPCO’s non-contact alignment (NCA) machine to automatically adjust vehicle toe to desired settings.

Learn moreEnd of Line

Buzz-Squeak-Rattle Systems

Our expertise in dynamic vehicle testing has allowed us to produce an extremely cost effective alternative to the test track.

Learn moreEnd of Line

Non-Contact Wheel Alignment

Our multi-line laser, computerized, non-contact wheel alignment system (NCA) is built to handle even the most unique tire shapes.

Learn moreEnd of Line

Roll Brake / Dynamic Vehicle Testing

Our roll brake or dynamic vehicle test systems simulate real world road conditions that provide precise, repeatable test results in a production environment.

Learn moreEnd of Line

Suspension Assembly and Alignment

Our suspension assembly and alignment systems are designed to align the axle before being installed into a vehicle—they can be operated manually, semi-automatically, or fully automatic.

Learn moreEnd of Line

Tire and Wheel Assembly

Our tire and wheel assembly machines offer all the customization required for seamless integration and all of our systems come with our patented robotic mounters and air over hydraulic inflators that maintain tire pressures to tight tolerances. With our tire pressure monitor support (TPM), customers are assured that their tires are always perfectly inflated. We also support stemmers, soapers, and loaders, and with our bead seat/load simulation, balancing, and uniform testers, our smart systems can accommodate any need.

Learn more