Smart Vaccine Storage & Dispensing

Services Provided

Hardware design, software design, prototyping, supply chain development, verification testing, value engineering, New Product Introduction, safety certification, manufacturing, after-market services, current product engineering

Key Technologies

- Robotic inventory system manages nearly 800 vaccines

- Dual-zone environment control (refrigeration/freezer) maintains CDC-compliant temperature zones with NIST traceability

- Remote diagnostics and FW/SW updates

- HIPAA compliant biometrically secure

- Relied on D&K Product Realization Process to significantly redesign and manufacture product

Business Outcomes

Commercialization of a reliable solution for the first smart vaccine storage handling system that is now being deployed into the field

Sinterstation Pro SLS

- Industrial Design

- Innovative Mechanism Design

- Frame, structure & skin design

- Thermal Analysis

- Stress Analysis

- Sophisticated Electrical Board Design

- Software Control Systems Design

- New Product Introduction (NPI)

- Manufacturing

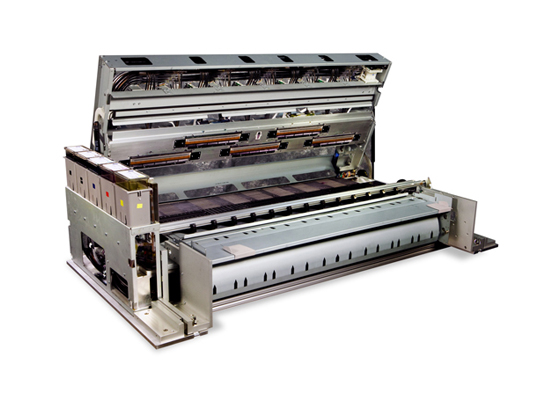

Wide Format Print Engine

- Full design, qualification and testing for the entire print engine

- Structure and Frame

- Ink Delivery System

- Consumable Ink Supply

- Paper Path Design

- Print Engine Pipeline

- Print Head Electronics

- Onboard Scanner

- Maintenance System

- New Product Introduction (NPI)

- Manufacturing

Cell Phone Recycling Kiosk

- Electromechanical Design

- Lighting & Vision System

- OCR Development

- Skins, Frame and Structure

- Machine Control System & firmware

- System Integration

- New Product Introduction (NPI)

- Manufacturing

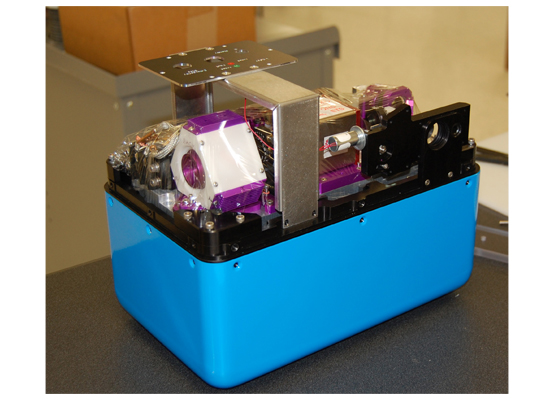

LENS FLUORSCENCE BIOMICROSCOPE

Utility-Scale Solar Power

- Design and develop complex cable harness systems

- Custom, low cost, high-reliability communication controllers operating in extremely harsh environments to manage critical information flow between large “dish groups” and centralized controllers

Inkjet Digital Photo Minilab

- Paper indexing systems

- Anti-skew mechanisms

- Two-axis cutter system

- Waste Disposal

- Back-side printer

- Photo Stacker

- Distributed design environment with offshore resources

- Transferred to manufacturing partner in Singapore

Photo Order Sorter

- Requirements refinement

- Rigorous architecture development and formalized architectural selection process

- Key component selection

- Electromechanical design

- Structural and nodal analysis

- Prototype development

- Handoff to client preferred CM

Low Cost Inkjet Printer

- Next-generation All-in-One low cost inkjet printer

- Servo development

- Writing systems

- Carriage dynamics

- Mechanical design

Inkjet Printer Accessories

- Inkjet printer accessories development

- Firmware development

- Complex plastic mechanism design

- Mechanical architecture

- Detailed design and testing of Hagaki card feeder

- 8 1/2 x 11 duplexer and paper handling device for multi-functional system

3D Printer

- Value-Engineering

- Cost Reductions

- Reliability Improvements

- Streamlined Supply Chain

- Manufacturing

- Field Engineering for Installation Support

- Maintenance Support

Label Printer

- Feasibility Analysis

- Mechanical Design

- Defined Hardware and Firmware Architecture

- Developed: Software Architecture, Subsystem, Writing System, Image,

- Pipeline, Firmware

- Prototype Development

- Design Verification Testing (DVT)

- Engineering Verification Testing (EVT)

- Design for Manufacturing (DFM)

- Manufacturing

Office Printer

- Ink delivery system

- Consumable ink supply

- Maintenance system

- System validation and verification

Label Print Engine

- Full design, qualification and testing for the entire print engine

- Structure and Frame

- Ink Delivery System

- Consumable Ink Supply

- Paper Path Design

- Print Engine Pipeline

- Print Head Electronics

- Onboard Scanner

- Maintenance System

- New Product Introduction (NPI)

INKJET CARTRIDGE REFILL KIOSK

- Mechanical Engineering

- Structural Design

- Pumps & Fluidics

- Vacuum System

- Electrical Tester

- Firmware Development

- New Product Introduction (NPI)

- Manufacturing

Consumer Scrapbook Cutter

Low cost architecture

Structure & drive system

Custom DC motor servo system

Prototype development

Transferred design to clients’ manufacturing partner in China

Performed product knowledge transfer to clients’ engineering staff

Documented all technical designs

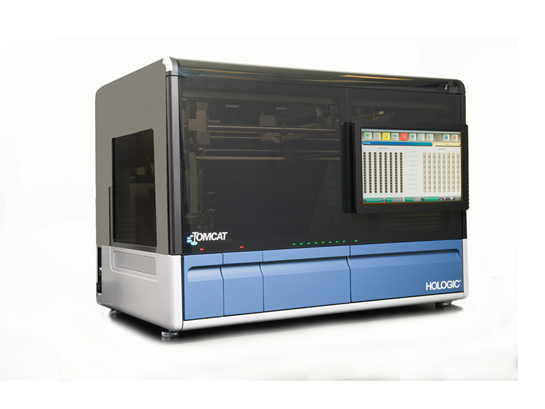

AUTOMATED SAMPLE PREPARATION INSTRUMENT

Services Provided:

Concept development, hardware design, software design, user interface, prototyping, supply chain development, verification testing, value engineering, New Product Introduction, safety certification, manufacturing, after-market services, current product engineering

Key Technologies:

- Dual XYZ Gantry robots nested together in a compact form factor

- Pick-and-Place Robot – Manages transport of multiple tube types at speeds up to 50 ips over 30” of travel

- Pipettor Robot – Manages aspiration and dispense between reagent, patient sample and output vials

- High speed, high precision XYZ coordinated motion

- Integrated compact vortexing and de/capping processing module

Distributed motion control topology – custom control boards through CAN bus interface - Tube barcode printing module integrated into patient workflow

- Master controller SW, modular motor and system embedded controller FW developed under ISO 13485 controls

- Used client’s design procedures to comply with Class II IVD and IE 61010

Business Outcomes:

Successfully developed a complex system automating patient sample preparation workflows with process controls that delivered on the client’s business goals of high throughput and reliability for increasing the usage of their clinical diagnostic equipment

FRACKING FIRING PANEL & SWITCH

- System used in oil and natural gas exploration

- Developed firing panel enclosure include electronics, firmware & PC application

- Created detailed design

- Procured parts

- Built prototypes

- Debug, test & verify prototype functionality

- Prototypes used in field testing

Traffic Enforcement Products

- Strategic relationship

- Product reliability improvements

- Cost reduction design

- New Product Introduction

- Singapore-based manufacturing

Mud Analyzer

- ATEX compliant system (European explosive atmosphere standard)

- Nitrogen generator design

- Key component selection (ATEX certified)

- Validation & verification

- Compliance documentation

- ATEX certification testing

- New Product Introduction (NPI)

- Manufacturing

- ATEX compliant system (European explosive atmosphere standard)

- Nitrogen generator design

- Key component selection (ATEX certified)

- Validation & verification

- Compliance documentation

- ATEX certification testing

- New Product Introduction (NPI)

- Manufacturing

Wireless Surveillance Camera

- Identify Product Requirements

- Generate Design Concepts

- Design architecture and electro-mechanical system for dome security camera

- New PCB and connections

- New enclosure, antenna and solar panel

- Dome architecture and mechanical design

Fracking Firing Panel & Switch

- Architect entire laser project system (25W optical power)

- Design of high power Red, Green, and Blue laser modules

- Design laser box enclosure; integrate all mechanical and electrical hardware

- Design system electronics to run the laser modules including thermal manage

Semiconductor Chip Handlers

- Multidisciplinary R&D capabilities including turnkey prototyping and manufacturing solutions for a worldwide market leader in the semiconductor test and chip handling industry that was looking for a flexible development partner to enhance its ability to bring quality, market-leading semiconductor handling products to its customer.

Refurbished Electronics Kiosk

- Frame, skin & structure

- Pick & place robot

- Product dispense & return to kiosk

- Machine control software

- Display cabinet with bin-level full variable color LED solutions

- Prototype development

- New Product Introduction (NPI)

- Manufacturing

Photo Booth

- Industrial Design

- Mechanical Design – all structural and cosmetic elements

- Electrical Design- lighting solution, sound, camera control & effects

- New Product Introduction (NPI)

- Manufacturing

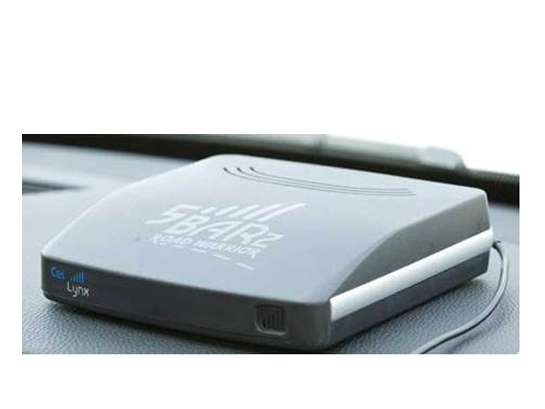

- Developed a PCA test-bed and proof of concept for challenging RF technology

- Support feasibility investigation

- Requirements definition and architecture

- Schematic integration of RF circuit architecture

- Development of controller module

- Mechanical development of shield and antenna prototypes

- Developed a PCA test-bed and proof of concept for challenging RF technology

- Support feasibility investigation

- Requirements definition and architecture

- Schematic integration of RF circuit architecture

- Development of controller module

- Mechanical development of shield and antenna prototypes

Coffe Kiosk

- Mechanical Engineering

- Structural Design

- Pumps & Fluidics

- Vacuum System

- Electrical Tester

- Firmware Development

- New Product Introduction (NPI)

- Manufacturing

Photo Kiosk

- Detailed design of paper layout

- Cross cutter systems

- Web & margin slitters

- Output paper path

- Paper waste handling

- Heaters

- Paper advance mechanisms

- Vacuum platen

- Overspray & aerosol collection

- Lead & web eade & fiducial sensing

- Vacuum hold down of prints

Rehabilitation Device

Services Provided:

Concept development, hardware design, software design, user interface, prototyping, supply chain development, safety certification, value engineering, New Product Introduction, regulatory submission, manufacturing, after-market services, current product engineering

Key Technologies:

- Two simultaneously activated control systems: Body weight unloading and patient motion tracking control

- Dynamic body weight support up to 200 lbs, and static support to 400 lbs

- Control system can track a patient going up to 4 mph

- Device operates independently and communicates wirelessly to the physical therapist via a PC and/or a handheld device

- Software and firmware developed in accordance with IEC 62304

- Compact architecture that allows use in hospital ceiling heights as low as 9 feet

- Designed and manufactured the system using our quality system

- Engaged early in the lifecycle with UL to pass all regulatory testing

- Managed the regulatory testing to IEC-60601-1 3rd edition with UL

Business Outcomes:

D&K Engineering took the product from concept to a sellable unit in less than 12 months, delivering the first units in time for a major trade show that yielded customer sales

HIV Diagnostic System

Services Provided:

Concept development, hardware design, software design, user interface, prototyping, supply chain development, safety certification, value engineering, New Product Introduction, regulatory submission

Key Technologies:

- Developed a semi-automatic automated Mixer, Spinner, Reader (MSR) device to enable processing of the disposable reagent cartridge

- Rugged, battery-powered unit

- Motion control and automation

- Electromechanical interlocks for safety

- Complex mechanism designs

- Mixer had precision orbital motion

- Complex spinner mechanism using multi-action sliding mechanism

- Optical magnification design for the Reader

- Designed the instrument using D&K’s Product Realization Process

Business Outcomes:

Successful field trials in Africa, delivering flow-cytometry equivalent T4 cell count at Point-of-Care, and at a fraction of the cost and processing time

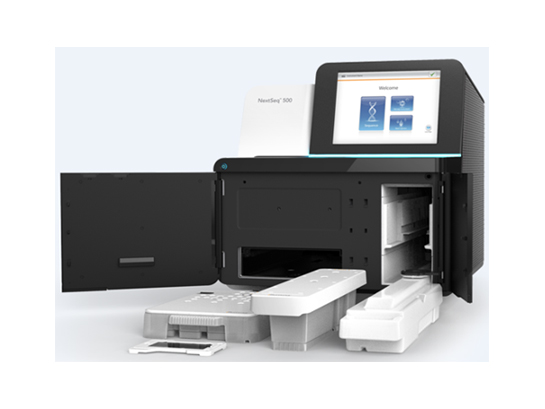

DNA Sequencing Consumables

- In-vitro Diagnostic Device

- Consumable architecture evaluation

- Design, build, test & debug prototype consumable

- Microfluidics, digital fluidics, system valves, seals, pumps & plastic housings

- Detailed design of final consumable

- System reliability & analysis

- Test plan development

- Consumable testing

Stent Manufacturing Process Development

DNA Sequencing Device

- Contract manufacturing of BeadXpress – DNA sequencing lab equipment

- Development of manufacturing automation systems for gene sequencing

- Contract manufacturing for multiple subsystems

Fitness Machine for the 50+ Age Market

- Development and manufacturing of a compact, light-weight, programmable resistance, free-motion, strength and range-of-motion exercise machine geared for the 50+ age market.

- The fitness equipment intended for home-use allows the user to exercise all the body’s muscles using complete hemispherical range of motion.

Man-Portable Laser

- Redesigned the optics and electronics for a laser that provides LIBS (Laser-

- Induced Breakdown Spectroscopy)

- Prototyped for stand-off explosives and drug detection operations at distances > 30 feet

- Re-packaged the technology from a lab environment to a rugged man-portable system for field soldiers